StiffClip® AL

Features

- Guide holes for fast and accurate connections

- Stiffeners for additional strength

- Manufactured from certified, 50ksi steel

- No labor spent cutting scrap angle

- Used in a variety of applications

- Extensively tested (reduces liability concerns associated with use of untested, miscellaneous untraceable material)

Order Information

| Designation | Qty/Box | Lbs/Box | Qty/Skid | Lbs/Skid |

| AL362 | 100 | 30 | 4,500 | 1,350 |

| AL600 | 100 | 52 | 4,500 | 2,340 |

| AL800 | 50 | 37 | 2,250 | 1,665 |

Nomenclature

StiffClip AL is available for varioius stud depths. To specify, multiply stud depth by 100.*

Example: 6″ stud depth

Designate: StiffClip® AL600

* The AL362 fits 3 ⅝” and 4” member depths.

** Stiffening ribs are not present in the AL800.

Material Composition

Catalogs

|

|

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

StiffClip® AL Downloads

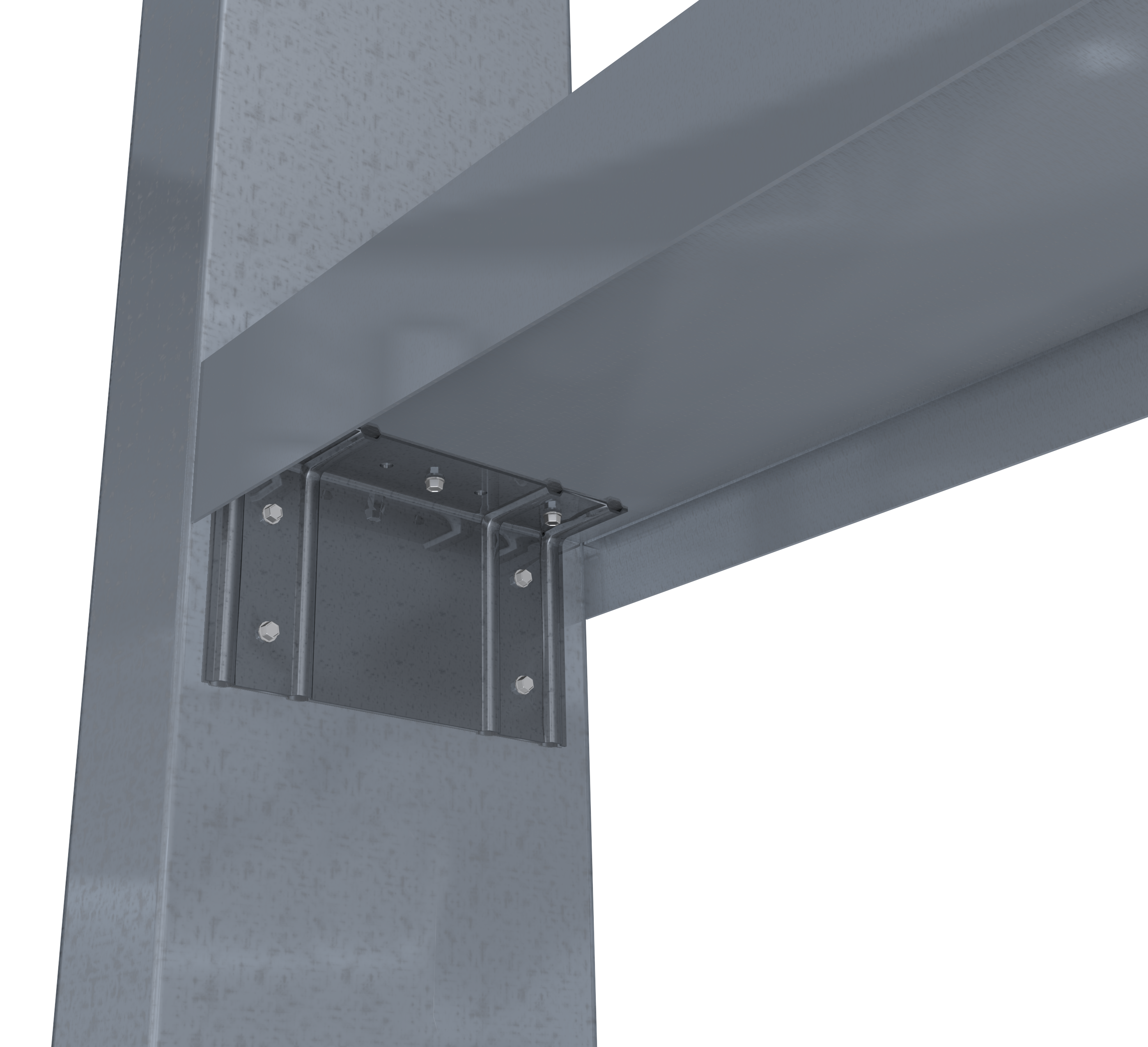

StiffClip® AL Applications

The attachment of StiffClip to the primary structure may be made with PAFs, screw/bolt anchors or weld and is dependent upon the base material (steel or concrete) and the design configuration.

All Purpose Rigid Connector - Window Sill

Installation Instructions

- Four #12 screws are attached to member through predrilled guide holes in the

- 3” leg. Attach short (1.5”) leg to structure/member either utilizing the pre-drilled guide holes or with weld (attachment through short leg is engineered by others).

- If pre-drilled holes are not able to be utilized, follow fastener manufacturer recommendations for screw placement.

Allowable Loads

Notes:

- Allowable load tables incorporate eccentric loading of fasteners attached 3/4″ from the heel of the clip. Values with welded connection may increase.

- The attachment of the 1.5″ leg of StiffClip AL is dependent on the allowable loads of the fasteners, and is to be designed by others.

- Fasten within ¾” from the angle heel (centerline of the 1½” leg).

- All guide holes may not require fasteners. Number of fasteners used is to be determined by designer.

- Stiffening ribs are not present in the AL800.

- StiffClip AL is tested to resist loads in horizontal, vertical, and lateral directions.

- Loads listed reflect force in a single direction. When multiple loads react on the connection, it is the responsibility of the designer to check the interaction of forces.

- Allowable loads are for attachment through 3″ leg only. Attachment through 1.5″ leg should be engineered. (See material composition above for calculation purposes.)

- Allowable loads have not been increased for wind, seismic, or other factors.

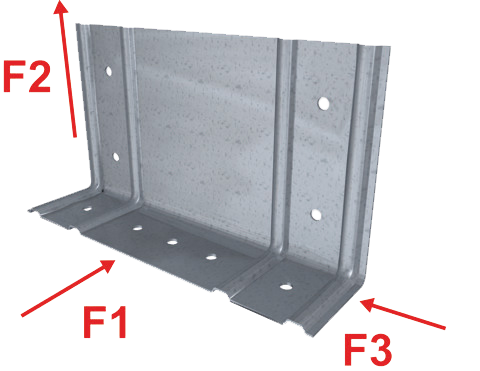

- Torsional effects are considered on screw group for F2 & F3 allowable loads. It is assumed that half of the torsional moment is taken by the connection to the structure and half is taken by the connection to the stud.

Load Direction

Follow us on Social Media