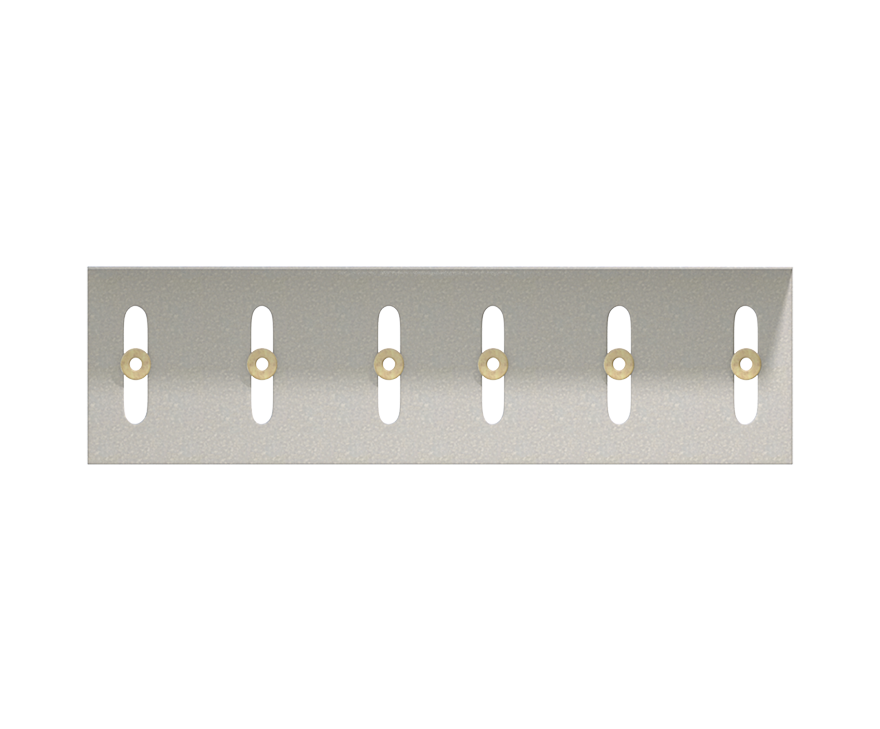

VertiClip® SLS

This vertical deflection strut is used to connect exterior cold-formed steel curtain wall studs to structural steel frame when large stand-off conditions exist, bypassing the primary structure, while allowing for a vertical deflection of the structure up to 1 ½” (¾” up and ¾” down). TSN’s patented Step Bushing Technology provides an anti-friction and anti-seizure connection between the clip and the stud web surface.

Features

- Variety of lengths available

- ICC-ES Approved, report #ESR-2049

- LARR Approved, report #25631

- Load-rated positive mechanical attachment at each stud

- Patented Step Bushing Technology provides friction-free motion for smooth vertical deflection

- Eliminates loose friction-held assemblies, heavy deep-leg track, & top row of wall bridging/strapping

- Load-rated #12 screws provided for vertical deflection connection to stud web

- Manufactured with certified, 50ksi, 68mil, G90 cold-formed steel

Order Information

Qty/Box

SLS362/400-9*

SLS362/400-12*

SLS600-12

SLS600-15

SLS600-18

SLS600-20

SLS600-24

SLS600-30

SLS600-36

SLS800-12

SLS800-15

SLS800-18

SLS800-20

Lbs/Box

SLS362/400-9*

SLS362/400-12*

SLS600-12

SLS600-15

SLS600-18

SLS600-20

SLS600-24

SLS600-30

SLS600-36

SLS800-12

SLS800-15

SLS800-18

SLS800-20

Qty/Skid

SLS362/400-9*

SLS362/400-12*

SLS600-12

SLS600-15

SLS600-18

SLS600-20

SLS600-24

SLS600-30

SLS600-36

SLS800-12

SLS800-15

SLS800-18

SLS800-20

Lbs/Skid

SLS362/400-9*

SLS362/400-12*

SLS600-12

SLS600-15

SLS600-18

SLS600-20

SLS600-24

SLS600-30

SLS600-36

SLS800-12

SLS800-15

SLS800-18

SLS800-20

Nomenclature:

VertiClip SLS is designated by stud depth and clip length required. Clip length includes a minimum of 3″ for steel (5.5″ for concrete) of clip material for attachment to structure added to stud depth, plus the distance of the stud from the structure.

Example:6″ stud, 6″ tolerance, 3″ to structure

Designate:VertiClip® SLS600-15

* Use of strengthening ribs and return bends varies with each clip.

Material Composition

Catalogs

|

|

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

US Patents #5,467,566 & #5,906,080

VertiClip SLS Downloads

VertiClip® SLS Applications

The attachment of VertiClip SLS to the primary structure may be made with PAFs, screw/bolt anchors or weld and is dependent upon the base material (steel or concrete) and the design configuration.

Steel Frame Bypass

Installation Instructions

- Attach SLS to structure with engineered attachment. Allow recommended minimum clip area for attachment.

- Align studs to SLS for plumb wall assembly.

- Fasten SLS to wall stud with provided screws through Step Bushings

Allowable Loads

Notes:

- VertiClip SLS series is designed to support horizontal loads and should not be used in axial-load-bearing wall construction.

- Allowable loads have not been increased for wind, seismic, or other factors.

- #12 screws are provided with each Step Bushing.

- Return lip added for clips longer than 20″.

- Allowable load tables incorporate eccentric loading of fasteners. Values with welded connection may increase.

- Fasten within ¾” from the angle heel (centerline of the 1½” leg) to minimize eccentric load transfer.

- Minimum 3″ of SLS required for attachment to structure to steel and 5.5″ min. with concrete.

- Total vertical deflection of up to 1½” (¾” up and ¾” down). Deflection requirements greater than ¾” up and down are available.

- For LRFD Design Strengths refer to ICC-ESR-2049.

Load Direction

Follow us on Social Media