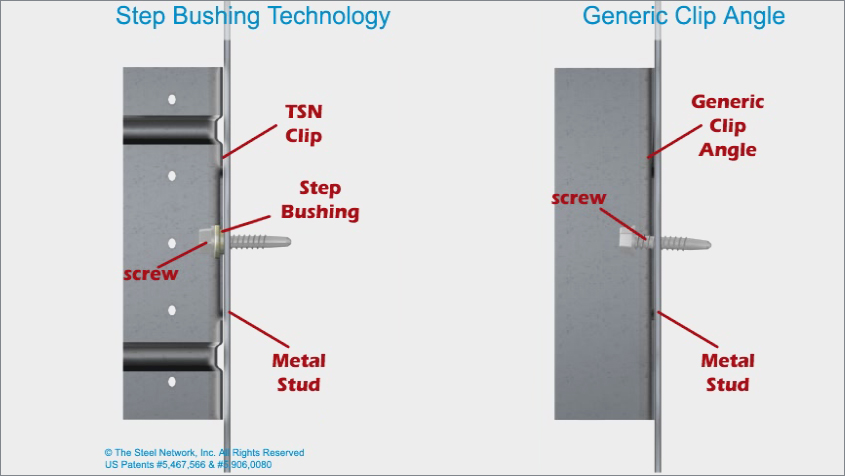

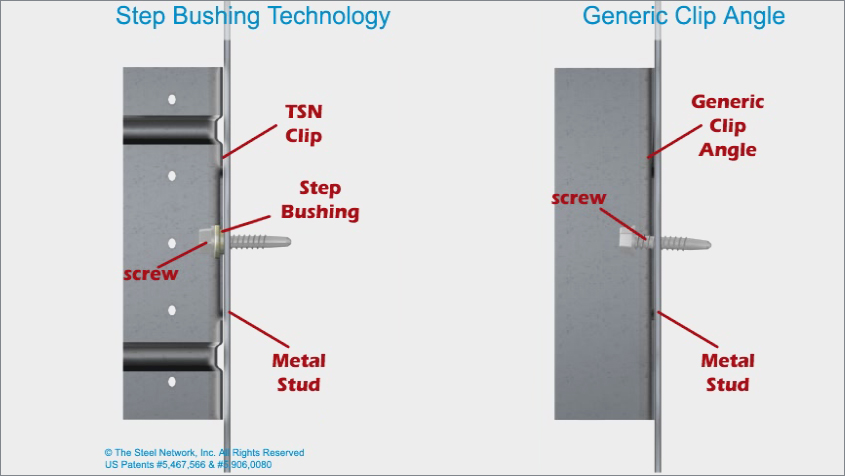

All structures deflect vertically, potentially causing costly damage to the structure and their finishes. True friction-free connections are required to ensure this damage does not occur. The Steel Network’s patented Step Bushing Technology® automatically creates the necessary gap for friction-free motion with no need to back out screws, providing installers with an easy-to-use connection. Step Bushings are pre-installed in TSN’s VertiClip®, DriftClip® and DriftTrak® product lines to allow the structure to deflect while leaving the stud undamaged and connection intact, increasing productivity, reducing liability and increasing lifespan, because… It’s What’s Inside that Counts!